Product Description

| Chain No. | Pitch

P |

Roller diameter

d1max |

Width between inner plates b1min mm |

Pin diameter

d2max |

Pin length | Inner plate depth h2max mm |

Plate thickness t/Tmax mm |

Transverse pitch Pt mm |

Breaking load

Q |

Weight per meter q kg/m |

||||||||||||||||||

| Lmax mm |

Lcmax mm |

|||||||||||||||||||||||||||

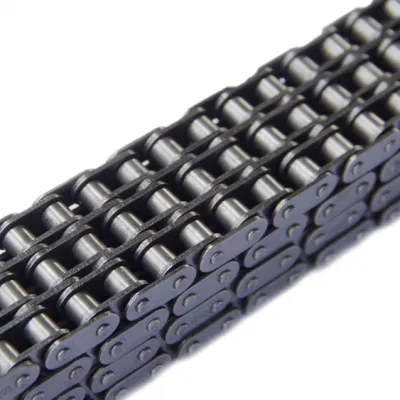

| 28BSS-3 | 44.450 | 27.94 | 30.99 | 15.90 | 184.20 | 188.70 | 36.70 | 7.50/6.-0-0. p. 211. Retrieved 17 May 2-0-0. p. 86. Retrieved 30 January 2015. Green 1996, pp. 2337-2361 “ANSI G7 Standard Roller Chain – Tsubaki Europe”. Tsubaki Europe. Tsubakimoto Europe B.V. Retrieved 18 June 2. External links Wikimedia Commons has media related to Roller chains. The Complete Xihu (West Lake) Dis. to Chain Categories: Chain drivesMechanical power transmissionMechanical power control Products Package Pictures:

Company Certificates: Why Choose Us 1. Reliable Quality Assurance System

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

What are the maintenance requirements for a bush chain?Maintaining a bush chain is essential to ensure its optimal performance and longevity. Here are the key maintenance requirements for a bush chain: 1. Regular cleaning: Regularly clean the bush chain to remove dirt, debris, and contaminants that can cause abrasion and accelerated wear. Use a brush or compressed air to clean the chain thoroughly. 2. Lubrication: Proper lubrication is crucial for the smooth operation and reduced friction of a bush chain. Apply the recommended lubricant to all the chain components, including the pins, bushings, and rollers. Follow the manufacturer’s guidelines for the appropriate lubricant type and frequency of lubrication. 3. Tension adjustment: Check the tension of the bush chain regularly and adjust it if necessary. Proper tension ensures optimal performance and reduces the risk of premature wear or failure. Consult the manufacturer’s guidelines or expert advice for the correct tensioning procedure specific to your chain. 4. Inspection: Conduct regular inspections of the bush chain to identify any signs of wear, damage, or misalignment. Inspect the chain for elongation, broken or damaged components, and misalignment. Replace any worn or damaged parts promptly to prevent further issues. 5. Replace worn components: Over time, the components of a bush chain, such as pins, bushings, and rollers, may wear out and require replacement. Monitor the wear levels of these components and replace them when they reach the manufacturer’s recommended limits. 6. Environmental considerations: Consider the operating environment of the bush chain and take appropriate measures to protect it. In corrosive or harsh environments, use corrosion-resistant chain materials or coatings to prevent accelerated wear. 7. Training and documentation: Ensure that maintenance personnel are properly trained in bush chain maintenance procedures. Keep detailed records of maintenance activities, including lubrication schedules, tension adjustments, and component replacements. By following these maintenance requirements, you can extend the lifespan of your bush chain and maintain its optimal performance. Regular maintenance and timely replacement of worn components will help prevent unexpected failures and costly downtime.

How do you troubleshoot common issues with bush chains?Troubleshooting common issues with bush chains involves identifying the problem and taking appropriate corrective actions. Here are some common issues and their troubleshooting steps: 1. Chain Misalignment: If the bush chain is misaligned, it can cause excessive wear, noise, and premature failure. To troubleshoot this issue, check the alignment of the sprockets and adjust them as necessary. Ensure that the chain runs smoothly and evenly on the sprockets without any binding or skipping. 2. Chain Binding: If the chain becomes stuck or binds during operation, it may be due to improper lubrication, debris accumulation, or worn-out components. Start by cleaning the chain and sprockets to remove any debris or contaminants. Lubricate the chain with the recommended lubricant to reduce friction. If the issue persists, inspect the chain for signs of wear and replace any worn-out components. 3. Excessive Chain Wear: Excessive chain wear can lead to elongation, reduced performance, and increased risk of failure. To troubleshoot this issue, measure the chain’s length and compare it to the manufacturer’s specifications. If the chain has elongated beyond the acceptable limits, it needs to be replaced. Additionally, inspect the chain for signs of pin and bushing wear, plate wear, or sprocket wear. Replace any worn components as necessary. 4. Insufficient Lubrication: Inadequate lubrication can result in increased friction, wear, and premature failure of the bush chain. If the chain appears dry or there are signs of insufficient lubrication, apply the appropriate lubricant to the chain according to the manufacturer’s recommendations. Ensure that the lubricant reaches all the critical components of the chain, including the pins, bushings, and rollers. 5. Chain Breakage: Chain breakage can occur due to excessive loads, sudden impacts, or worn-out components. To troubleshoot this issue, inspect the chain for any signs of damaged or broken links. Identify the cause of the breakage, such as overload or impact, and address it accordingly. Replace the broken chain links with a new chain segment and ensure proper installation. 6. Excessive Noise and Vibration: Unusual noise and vibration during chain operation can indicate underlying issues. Inspect the chain for signs of misalignment, worn-out components, or inadequate tension. Address the specific cause by adjusting the alignment, replacing worn parts, or adjusting the tension to reduce noise and vibration. It’s important to consult the manufacturer’s guidelines and recommendations for troubleshooting specific issues with bush chains. Regular inspection, proper lubrication, and timely maintenance can help prevent common issues and ensure the reliable and efficient operation of the bush chain.

What is a bush chain and how does it work?A bush chain, also known as a bush roller chain or a bushing chain, is a type of roller chain commonly used in mechanical power transmission systems. It consists of a series of interconnected links, known as bushings, that are joined together by pins. The bushings are cylindrical metal sleeves with internal bearings that rotate on the pins. The working principle of a bush chain is based on the interaction between the rotating bushings and the teeth of the sprockets. The chain is wrapped around two or more sprockets, with one sprocket being the driver and the other(s) being the driven. As the driver sprocket rotates, it pulls the chain, causing the bushings to rotate on the pins. Each bushing has an outer surface that comes into contact with the sprocket teeth. The engagement between the sprocket teeth and the bushings’ outer surface creates the driving force, allowing power to be transmitted from the driver sprocket to the driven sprocket(s). This rotational motion transfers torque and enables the movement of various mechanical components or systems connected to the driven sprocket(s). The bush chain design provides several advantages, including high tensile strength, flexibility, and the ability to transmit power over long distances. The bushings and pins are typically made of hardened steel to ensure durability and resistance to wear. Lubrication is essential to reduce friction and prevent premature wear of the bushings and pins. Bush chains are widely used in various applications, such as industrial machinery, agricultural equipment, automotive systems, and conveyor systems. They are favored for their reliability, efficiency, and ease of installation. Proper maintenance, including regular lubrication and tension adjustment, is necessary to ensure the smooth operation and longevity of a bush chain.

Tags: Uncategorized

| ||||||||||||||||||||